MEMBRANE ELEMENTS

Product Images

SPECIFICATIONS

| Description | Applied Pressure (psi / bar) | Permeate Flow Rate (gpd / lpd) | Nominal Salt Rejection % |

|---|---|---|---|

| SE1– 2521 | 800 / 55.16 | 250 / 0.95 | 99.75 |

| SE1– 2540 | 800 / 55.16 | 500 / 1.89 | 99.75 |

| SE1– 4040 | 800 / 55.16 | 1800 / 6.81 | 99.75 |

| SE1– 8040 | 800 / 55.16 | 7500 / 28.39 | 99.75 |

Warranty Evaluation Test Conditions: Permeate flow and salt rejection based on the following test conditions: 32,000 ppm NaCl, pressure specified above, 77°F / 25°C and the following recovery rates; SE1–2521 15%, SE1–2540 15%, SE1–4040 15%, SE1–8040 15%. Permeate flows for individual elements may vary +/-20%. For the purpose of improvement, specifications may be updated periodically.

OPERATING LIMITS

| Membrane Type | Polyamide Thin-Film Composite |

| Maximum Operating Temperature (°F / °C) | 113 / 45 |

| Maximum Operating Pressure (psi / bar) | 1200 / 82.70 |

| pH Range, Continuous OperationA | 2 -11 |

| pH Range, Short Term Cleaning (30 Min.) | 1 -13 |

| Maximum Feed Silt Density Index (SDI) | 5 |

| Chlorine / Chloramine Tolerance (ppm) | 0 |

| Maximum Feed Flow Rate (gpm) | 2.5” = 6, 4.0” = 14, 8.0” = 75 |

A. Maximum temperature for continuous operations above pH10 is 95°F / 35°C.

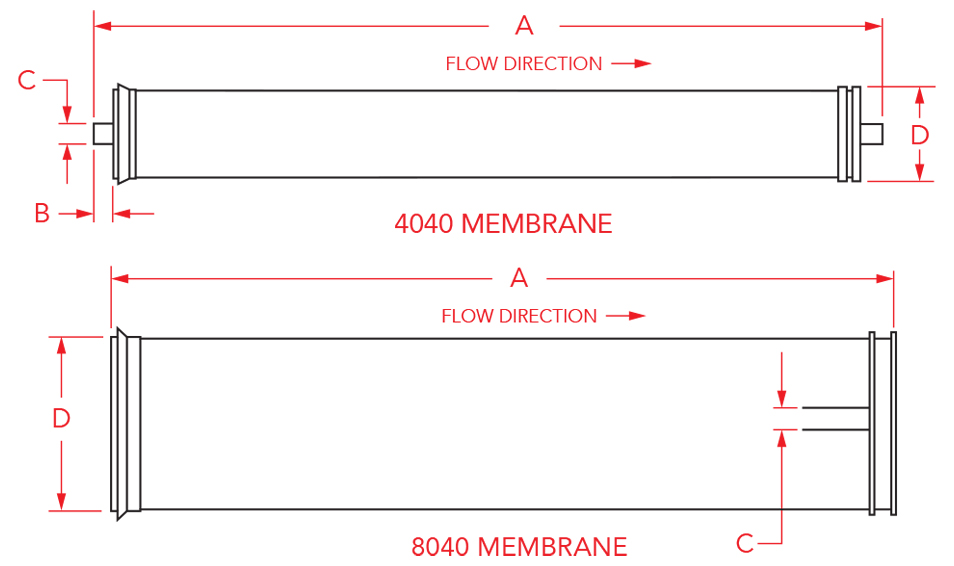

| DIMENSIONS (IN / MM) | |||||

|---|---|---|---|---|---|

| Description | A | B | C | D | |

| SE1– 2521 | 21 / 533 | 1.12 / 28.50 | 0.75 / 19.10 | 2.40 / 61 | |

| SE1– 2540 | 40 / 1016 | 1.12 / 28.50 | 0.75 / 19.10 | 2.40 / 61 | |

| SE1– 4040 | 40 / 1016 | 1.04 / 26.50 | 0.75 / 19.10 | 3.90 / 99 | |

| SE1– 8040 | 40 / 1016 | N / A | 1.12 / 28.50 | 7.91 / 201 | |

Note: All 2521 and 2540 elements fit nominal 2.50” I.D. membrane housings, all 4040 elements fit nominal 4.00” I.D. membrane housings, and all 8040 elements fit nominal 8.00” I.D. membrane housings.

Proper start-up of reverse osmosis water treatment systems is essential to prepare the membranes for operating service and to prevent membrane damage due to overfeeding or hydraulic shock. Before initiating system start-up procedures, membrane pretreatment, loading of the membrane elements, instrument calibration and other system checks should be completed.

Avoid any abrupt pressure or cross-flow variations on the spiral elements during start-up, shutdown, cleaning or other sequences to prevent possible membrane damage. During start-up, a gradual change from a standstill to operating state is recommended as follows:

- Feed pressure should be increased gradually over a 30-60 second time frame.

- Cross-flow velocity at set operating point should be achieved gradually over 15-20 seconds.

- Permeate obtained from first hour of operation should be discarded.

- Maximum pressure drop across an entire pressure vessel (housing) is 15 psi / 1.03 bar.

- Avoid static permeate-side backpressure at all times.

Under certain conditions, the presence of free chlorine, chloramines and other oxidizing agents will cause premature membrane failure. Since oxidation damage is not covered under warranty, the manufacturer recommends removing all oxidizing agents by pretreatment prior to membrane exposure. Please contact the manufacturer or your supplier for more information.

Do not use this initial permeate for drinking water or food preparation. Keep elements moist at all times after initial wetting. To prevent biological growth during prolonged system shutdowns, it is recommended that membrane elements be immersed in a preservative solution. Rinse out the preservative before use. For membrane warranty details, please contact the manufacturer or your supplier for more information.

If operating limits and guidelines given in this product specification sheet are not strictly followed, the warranty will be null and void. The customer is fully responsible for the effects of incompatible chemicals and lubricants on elements. Use of any such chemicals or lubricants will void the warranty. These membranes may be subject to drinking water application restrictions in some countries: please check the application status before use and sale. The use of this product in and of itself does not necessarily guarantee the removal of cysts and pathogens from water. Effective cyst and pathogen reduction is dependent on the complete system design and on the operation and maintenance of the system.

No freedom from infringement of any patent owned by the manufacturer or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, customer is responsible for determining whether products and the information in this document are appropriate for customer’s use and for ensuring that customer’s workplace and disposal practices are in compliance with applicable laws and other governmental enactments. The claims made may not have been approved for use in all countries. The manufacturer assumes no obligation or liability for the information in this document. AXEON reserves the right to update this information periodically for the purposes of quality and accuracy. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

THE RIGHT SOLUTION FOR YOU

Contact us today for more information about our products and services.

CONTACT US