Technical Articles

Key Membrane Performance Metrics for Optimizing Reverse Osmosis Systems

Reverse osmosis (RO) is a widely used water purification technology that removes impurities and dissolved solids from water through a semipermeable membrane. The efficiency and effectiveness of an RO system largely depends on the performance of its membrane. Understanding the key performance metrics associated with RO membranes is crucial for optimizing system operation and ensuring high-quality purified water. In this blog post, we will look into the essential performance metrics and factors affecting the efficiency of reverse osmosis systems.

-

Permeability

Permeability refers to the capacity of the membrane to allow water to pass through it. It is typically measured in liters per square meter per hour (LMH) and indicates how much permeate (purified water) can be produced under specific conditions.

Key Influencing Factors:- Feed Water Quality: The concentration of dissolved solids, temperature, and presence of organic matter can significantly affect permeability. Clean, low-TDS water will result in higher permeability rates.

- Operating Pressure: Higher pressures generally increase permeability, but excessive pressure can lead to increased energy costs and potential membrane damage.

-

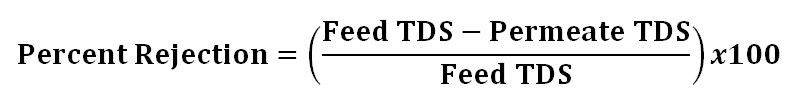

Salt Rejection Rate

Salt rejection rate measures the percentage of dissolved salts (total dissolved solids or TDS) that are removed from the feed water during the reverse osmosis process. A high rejection rate is essential for producing high-quality purified water.

Key Influencing Factors:

- Membrane Material: Different membrane materials exhibit varying rejection capabilities. Membranes made from polyamide have high rejection rates, often exceeding 95% for common impurities.

- Operating Conditions: Like permeability, the salt rejection rate is affected by factors such as operating pressure and temperature. Higher temperatures can enhance rejection efficiency but also require careful monitoring to prevent membrane damage.

-

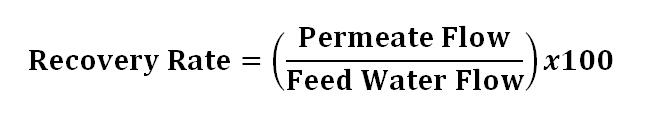

Recovery Rate

Recovery rate is defined as the ratio of the volume of permeate produced to the volume of feed water supplied to the system. It is expressed as a percentage and is vital for assessing the efficiency of an RO system.

Key Influencing Factors:

- System Design: The layout of the RO system, including the arrangement of membrane elements and the number of stages, affects the recovery rate.

- Feed Water Composition: Higher concentrations of dissolved solids can lower recovery rates due to increased osmotic pressure, which limits the water that can be effectively filtered.

-

Differential Pressure (ΔP)

Differential pressure indicates the pressure difference between the inlet (feed side) and the outlet (concentrate side) of the membrane. Monitoring ΔP is crucial for identifying fouling or scaling issues within the membrane system.

Key Influencing Factors:- Fouling and Scaling: As membranes accumulate foulants, ΔP increases, indicating that the membrane surface is being blocked and is less effective at filtration.

- Flow Rates: Adjustments to feed flow rates can also alter ΔP, necessitating continuous monitoring to ensure optimal performance.

-

Silt Density Index (SDI)

Silt Density Index (SDI) serves as an indicator of the fouling potential of feed water. It evaluates the presence of suspended solids that could contribute to membrane fouling. An SDI value of less than 3.0 is generally recommended for RO systems.

Key Influencing Factors:- Pre-treatment Efficiency: Effective pre-treatment processes (such as multimedia filtration and activated carbon filtration) can significantly reduce SDI, thus enhancing RO performance.

- Water Source Quality: The inherent quality of the raw water source plays a critical role in SDI values, impacting the overall sustainability of the RO system.

Conclusion

Optimizing a reverse osmosis system requires a thorough understanding of several key performance metrics, including permeability, salt rejection rate, recovery rate, differential pressure, and silt density index. By regularly monitoring these metrics and adjusting operational parameters accordingly, operators can enhance system effectiveness, reduce maintenance costs, and ensure the consistent production of high-quality purified water.

By paying close attention to these performance metrics, you can maximize the life span of your membranes and the overall efficiency of your reverse osmosis system. Whether you’re operating in a municipal water treatment facility or an industrial application, understanding these critical performance factors is essential for achieving optimal results.

About AXEON Water Technologies

At AXEON Water Technologies, we are dedicated to providing innovative and reliable water filtration solutions for commercial and industrial applications. Our extensive range of high-performance membranes and systems include options tailored for your projects, ensuring that you find the right solutionfor your specific requirements.

Expert Guidance and Solutions

Our team of water treatment experts are available to assist you in optimizing your reverse osmosis systems. Whether you are facing challenges with fouling, scaling, or overall system efficiency, we can offer tailored advice and solutions based on your unique situation. We understand that each water source presents its own challenges, and we are here to help you navigate these complexities to achieve optimal performance.

Cutting-Edge Technologies

AXEON's commitment to innovation means we continually refine our membrane technologies to enhance performance and reliability. Our membranes are engineered to maximize filtration efficiency while minimizing operational costs. We leverage advanced materials and designs, ensuring that our products are not only effective but also sustainable.

Support and Resources

In addition to our product offerings, we provide comprehensive resources to help our customers stay informed and proactive. From detailed technical specifications and application guides to educational materials on maintaining system performance, our goal is to empower our clients to make knowledgeable decisions regarding their RO systems.

Training and Expertise Development

We recognize the importance of training and expertise development. To that end, AXEON Water Technologies offers training programs designed to equip operators and engineers with the knowledge needed to optimize reverse osmosis systems effectively. Our workshops cover a range of topics, including membrane selection, operational best practices, troubleshooting, and maintenance techniques. By fostering a deeper understanding of membrane performance metrics and system operation, we aim to enhance the competency of your team and ultimately improve the overall efficiency of your water treatment processes.

THE RIGHT SOLUTION FOR YOU

Contact us today for more information about our products and services.

CONTACT US