Technical Articles

Efficient water treatment solutions are more critical than ever for ensuring operational success and sustainability. Ion exchange systems have emerged as a powerful tool in addressing various water purification needs across industries. From enhancing production processes to reducing environmental impact, these systems offer a multitude of benefits.

In this blog, we'll explore six key advantages of implementing ion exchange systems in industrial applications. Understanding these benefits can enhance your business’s efficiency and compliance in handling complex separation tasks and improving water quality.

Basic Principles of IonExchange

Ion exchange is a reversible chemical process where ions from a solution are exchanged for similarly charged ions attached to an immobile solid particle. Think of it as a sophisticated swap meet at a molecular level, where unwanted ions are traded for more desirable ones. The Exchange Process Initial Contact: Contaminated water passes through a bed of ion exchange resin. Ion Transfer: Undesirable ions in the water are attracted to the resin. Exchange: Target ions are captured while preferred ions are released. Result: Purified water exits the system.1. High Purification Efficiency

Ion exchange systems excel in their ability to selectively remove specific ions from water, achieving exceptional purification levels. This process replaces unwanted ions in water with better ones, usually using a resin bed. The efficiency of ion exchange can be expressed using the following equation:Removal Efficiency = ((Influent Concentration - Effluent Concentration) / Influent Concentration) × 100%

The exceptional purification capabilities of ion exchange make it ideal for applications that demand ultrapure water, such as in the electronics sector and pharmaceutical production.2. Customizable Treatment

One of the most significant advantages of ion exchange systems is their adaptability to specific contaminant profiles. By selecting appropriate resins, these systems can be tailored to target particular ions of concern. This customization allows industries to address their unique water quality challenges effectively. A power plant uses cation exchange resin to eliminate calcium and magnesium ions that cause hardness, while a semiconductor manufacturer uses a mixed-bed system to produce ultra-low conductivity water.3. Cost-Effective Operation

Ion exchange systems offer a cost-effective solution for water treatment, particularly when compared to other technologies like reverse osmosis. The operational costs are generally lower due to:- Reduced energy consumption

- Minimal chemical usage in certain applications

- Lower maintenance requirements

4. Continuous Operation Capability

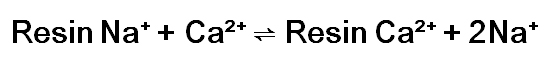

The ability to operate continuously is a crucial advantage of ion exchange systems in industrial settings. This is made possible through the regeneration process, which restores the ion exchange capacity of the resin. The regeneration cycle can be represented by the following simplified reaction:

During regeneration, the direction of this reaction is reversed, allowing the resin to be reused multiple times. This continuous operation capability ensures uninterrupted water treatment, which is essential for many industrial processes.

5. Minimal Waste Production

Compared to other water treatment technologies, ion exchange systems generally produce less waste. Unlike reverse osmosis, which can generate significant volumes of concentrate, ion exchange primarily produces waste during the regeneration process. This waste usually comes as a concentrated brine solution, which is often easier to manage than the constant concentrate flow from membrane systems.6. Scalability and Space Efficiency

Ion exchange systems are highly scalable, making them ideal for various industrial uses, from small businesses to large treatment plants. The modular nature of these systems allows for easy expansion as treatment needs grow. Additionally, ion exchange units are generally compact, requiring less floor space compared to other treatment technologies. This space efficiency is particularly valuable in industrial settings where real estate is at a premium.Conclusion

Ion exchange systems offer a multitude of benefits for industrial water treatment processes. Their high purification efficiency, cost-effectiveness, continuous operation, low waste production, customizability, and scalability make them appealing to many industries. As water quality standards tighten and industries pursue sustainable treatment options, ion exchange technology will likely become more important in industrial water treatment. Industries can ensure a steady supply of high-quality water while improving efficiency and reducing their environmental impact. As technology advances, ion exchange systems will continue to improve, becoming essential for industrial water treatment.Take the Next Step

Ready to explore how ion exchange systems can benefit your industrial operations? Connect with our experts to discuss your specific needs and discover the optimal solution for your application. Our team can help you evaluate your requirements and design a system that delivers the results you need.THE RIGHT SOLUTION FOR YOU

Contact us today for more information about our products and services.

CONTACT US